In March 2022, the Integrated Group of the Joint Prevention and Control Mechanism of the State Council issued the Implementation Guidelines for Regional Novel Coronavirus Nucleic Acid Testing Organizations (Third Edition), which stipulates that in order to adapt to the characteristics of rapid transmission of COVID-19 mutants such as Omicron, the nucleic acid testing within the designated scope should be completed within 24 hours, so as to furtherly improve the ability of "early detection" of the epidemic. This is undoubtedly a higher requirement for nucleic acid detection speed and throughput. Manual processing is difficult to complete the detection task quickly. The automatic sample pipetting system is the ultimate sharp tool to control virus transmission.

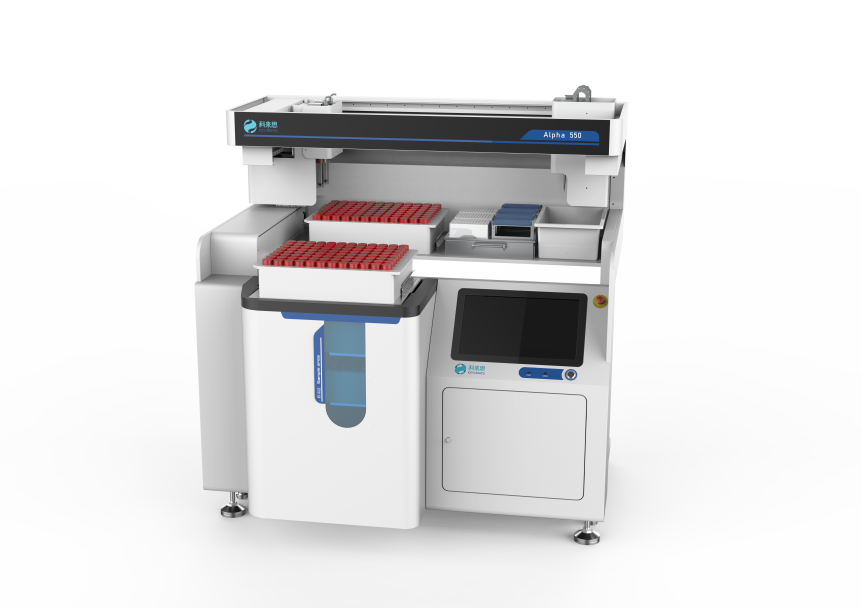

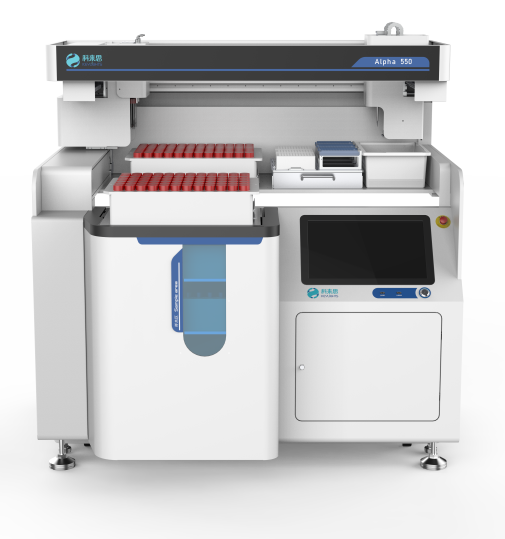

Recently, the Automatic Sample Pipetting System AIpha 550, specially designed for the PCR laboratory, was approved to be produced by Keylights & Keysmile. It makes full use of the existing laboratory space and equipment to pretreat test samples, which can be used for large-scale nucleic acid screening of COVID-19. It is safe, reliable, efficient, stable, compatible, information-traceable, and easy to operate. It can greatly improve the laboratory nucleic acid detection capability in a short time.ONE Product Introduction

Automatic Sample Pipetting System is consisted of a frame, a sample pipetting mechanism and a software system. It can be embedded in a biosafety cabinet, and no new laboratory needed to be built. November 19, The instrument has obtained the Class I Medical Device product registration certificate (Product Registration Number: 渝械備20220201) and production registration certificate (Production Registration Number: 渝藥監(jiān)械生產(chǎn)備20220023號(hào)) , and will be put into the market on a large scale to assist nucleic acid detection.

TWO Applicable Scenes

- COVID-19 Nucleic Acid Testing Laboratory

- CDC / Hospital Laboratory

- General Molecular Diagnostic Laboratory

THREE Product Advantages

SAFETY PROTECTION

- Embedded in biosafety cabinet; sample tube loaded with cap to avoid cross contamination

- Automatic de-capping and re-capping, no manual operation needed to reduce human error

- Equipped with liquid drip prevention design and pipetter tip waste recycling area to avoid contamination between samples

- One-tap emergency stop function, personal safety was taken into adequate consideration

EFFICIENCY AND RELIABILITY

- 550 tubes/hour, saving manpower and space investment with high daily throughput of 13000 tubes

- 2 three-axis grippers cooperate to grasp the tube body and cap to avoid the risk of dropping

- Highly intelligent operation management to effectively handle with abnormal sample tubes without an interruption in system operation

- Whole-process automation, including tube gripping, barcode scanning, sample cap de-capping, sample pipetting and sample cap re-capping function

- Micron-level precision control to ensure the sample pipetting accuracy; Positioning accuracy of XYZ axis manipulator is ± 0.1mm

- Use mature and stable control system as the control core, with strong anti-interference ability, convenient use, clearer and more practical logic processing to ensure more safe and reliable motion control of the product

COMPATIBILITY

- Compatible with 5mL-30mL sample tubes; customization available for sample tubes of other specifications

- Supportive for both one-dimensional barcode and two-dimensional barcode

- Adaptable to microwell plates with various specification

- Compatible with mixed sampling detection mode, supporting single sample detection, 5 mixed 1, 10 mixed 1, 20 mixed 1 sampling tubes, direct sampling without taking out swabs

INFORMATION TRACEBACK

- Track and record the whole process information, monitor the operation status in real time, and save the operation log

- Implement the interface to laboratory information management system

- Equipped with dual USB ports and LAN port

- Equipped with wireless WiFi module

EASY OPERATION

- 15.5-inch HD touch screen, user-friendly operation interface

- One-tap start with full intelligent operation process

- Three 96-sample racks can be loaded at once and form a continously independent working time up to 30 minutes. A single person can easily manage 6 instruments.

CONVENIENT AND EASY TO USE

- The base is equipped with high-strength rollers, which makes the instrument easily movable by a single person, and faciliates the installation and commissioning on site and the replacement of the biosafety cabinet

- Drawer-type consumable storage device for convenient replacement of consumables

- Moderate size, suitable for mainstream dual-seat biosafety cabinet, with table height adjustment device

FOUR System Parameter

| Model | Alpha 550 Sample Pipetting System | Touch-Screen | 15.5 inches wireless touch-screen |

| Maximum Pipettiing Speed | 550 sample tubes/H, 13s/sample tube | Cover Opening Number | 2 |

| Barcode Reading | Both liner barcode and 2D barcode | Throughput | 3 groups*96 positions |

| Sampling Mode | Automatic sample processing | Pipettor Quantity | 2 |

| Pipetting Volume | 10μL-1000μL | Barcode Scanning Positions | 2 |

| Deep Microplate Type | 96 positions | Deep Microplate Stations | 3, compatible with various models of deep microplate |

| Mechanical Gripper Location Accuracy | X-Y-Z location, ±0.1mm | Pipetting Precision | 10μL<5%; 100μL<2%; 1000μL<1% |

| Sample Tube Type | Perfectly compatible with 5mL-30mL sample tubes | Liquid Level Detection | Pneumatic liquid level detection |

| Dimensions | 1250mm(W)*1015mm(D)*1300mm(H) | Dimensions of Parts Embedded in Biosafety Cabinet | 1250mm(W)*521mm(D)*496mm(H) |